+86-13349293098

+86-13349293098

Leave Your Message

-

Contact Phone

Contact Phone -

Contact WhatsApp

Contact WhatsApp -

Contact Email

Contact Email

The selection of the right Dump Bed Cylinder is crucial for operational efficiency in the construction and transportation sectors. According to a recent report by the Hydraulic Institute, the misuse of dump bed cylinders can lead to costly downtime and safety hazards. Expert John F. Harlow, a hydraulic systems engineer, emphasizes, "Choosing the right cylinder can often mean the difference between success and failure in hauling operations."

Various factors influence this choice. Load capacity, extension length, and cylinder material are all critical considerations. The industry standard suggests that a mismatch can result in up to a 30% decrease in performance. While many operators focus solely on price, durability and compatibility should not be overlooked. A poorly matched cylinder can cause mechanical failures.

Making an informed decision about Dump Bed Cylinders requires careful evaluation. These components are not just mechanical parts; they are essential to the safety and effectiveness of your fleet. Each application may demand specific attributes. Operators often overlook these details, risking both profitability and safety. Learning from experience can guide future selections to better meet operational needs.

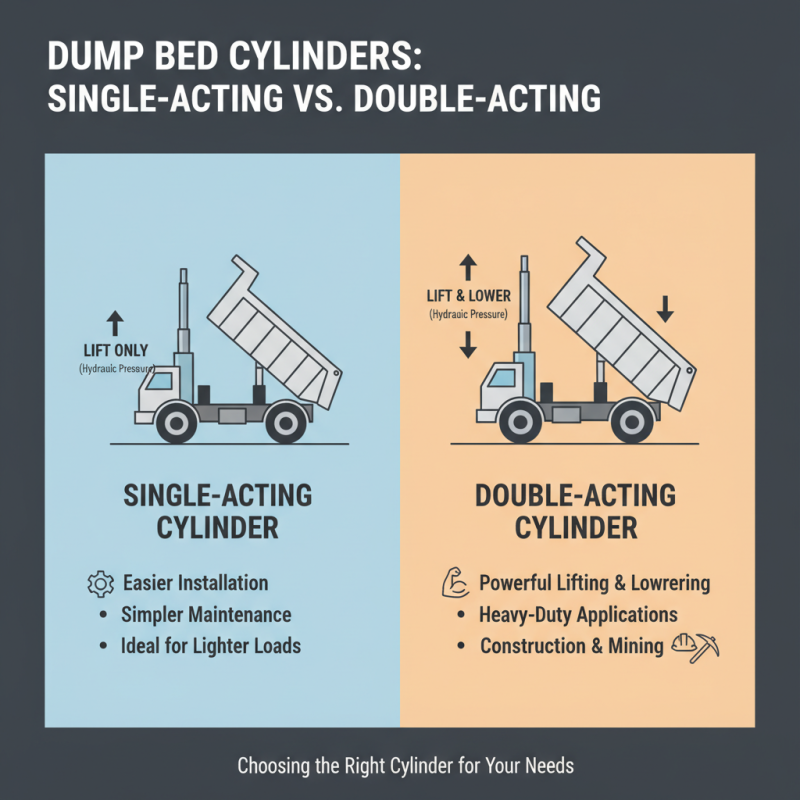

When choosing the right dump bed cylinder, understanding the various types is crucial. There are single-acting and double-acting cylinders, each serving different applications. Single-acting cylinders operate using hydraulic pressure for lifting. Single-acting cylinders are easier to install and maintain. However, they may not provide the power needed for heavier loads. Double-acting cylinders, on the other hand, can lift and lower loads efficiently. This makes them ideal for heavy-duty applications, such as construction and mining.

To make the right choice, consider the load capacity you need. According to industry reports, the standard load capacity for most dump bed cylinders ranges from 5,000 to 20,000 pounds. Understanding your operational requirements will help in selecting the appropriate size and type.

A good tip is to check the rod diameter. A thicker rod can handle more stress. Ensure you assess the hydraulic fluid compatibility, as different materials can impact performance. Remember, not all cylinders are interchangeable; some can risk safety and efficiency. Reflecting on these factors can lead to a more informed decision for your specific needs.

When selecting a dump bed cylinder, key specifications play a crucial role. The cylinder's capacity is paramount. Many industry experts suggest capacities ranging from 2 to 10 tons. This choice depends on the weight of the materials you frequently transport. A mismatch can lead to underperformance or potential damage. Consider the lifting speed as well. Ideal lift times should be under 30 seconds for efficiency in operation.

Another critical specification is the bore size. A larger bore can provide more power. However, it might also lead to increased weight. Consult reports indicating that a 4-inch bore offers a good balance for most applications. Additionally, check for stroke length. An optimal stroke length should match your truck's height. A limited stroke can create operational challenges during loading and unloading.

Don’t overlook installation and maintenance requirements. Some users find complex setups daunting. Regular maintenance is essential to ensure longevity and performance. Neglecting it can lead to hydraulic fluid leaks or cylinder fatigue. Doing thorough research on these aspects can save time and costs in the long run. Choosing the right dump bed cylinder is not just about specifications. It involves understanding your unique needs and potential limitations in the field.

Evaluating load capacity is crucial for selecting the right dump bed cylinder. A cylinder must handle the maximum weight without compromising safety. According to industry studies, a cylinder should typically have a load capacity that exceeds 150% of the maximum anticipated load. This ensures reliability under pressure, especially in demanding environments.

Different projects require varying load capacities. For example, light-duty trucks often need cylinders rated between 5,000 to 10,000 pounds. Conversely, heavy-duty applications may demand cylinders with capacities exceeding 15,000 pounds. It’s vital to consider both the weight of the payload and the dynamic forces during operation. A miscalculation can lead to cylinder failure and safety hazards.

Additionally, not all cylinders are built the same. Material quality, design, and manufacturing standards significantly impact performance. Some reports highlight that improper installation can reduce a cylinder's effectiveness by up to 30%. Regular maintenance is essential for optimal function. Inspect seals and hardware routinely to prevent leaks and failures. The goal is to ensure that your dump bed cylinder operates safely and efficiently under all conditions.

When selecting a dump bed cylinder, compatibility with the hydraulic system is crucial. A well-matched hydraulic system enhances dump bed performance significantly. According to industry reports, nearly 40% of hydraulic failures stem from improper component compatibility. This highlights the importance of choosing the right cylinder for your specific application.

Hydraulic systems operate under high pressures. Using the wrong cylinder can compromise efficiency and safety. For instance, a cylinder designed for lighter loads may fail under heavy stress. This can lead to unexpected downtime, costing businesses significantly. Ignoring system specifications may result in poor performance or even catastrophic failures.

Moreover, different hydraulic fluids can impact cylinder longevity. Some seals may degrade faster in particular fluids. This inconsistency can lead to leaks, which are not just inefficient but also hazardous. Regular inspections and assessments are essential. Identifying potential compatibility issues early can save time and resources. Would considering every component’s specifications lead to a smoother operation? It’s an area worth contemplating.

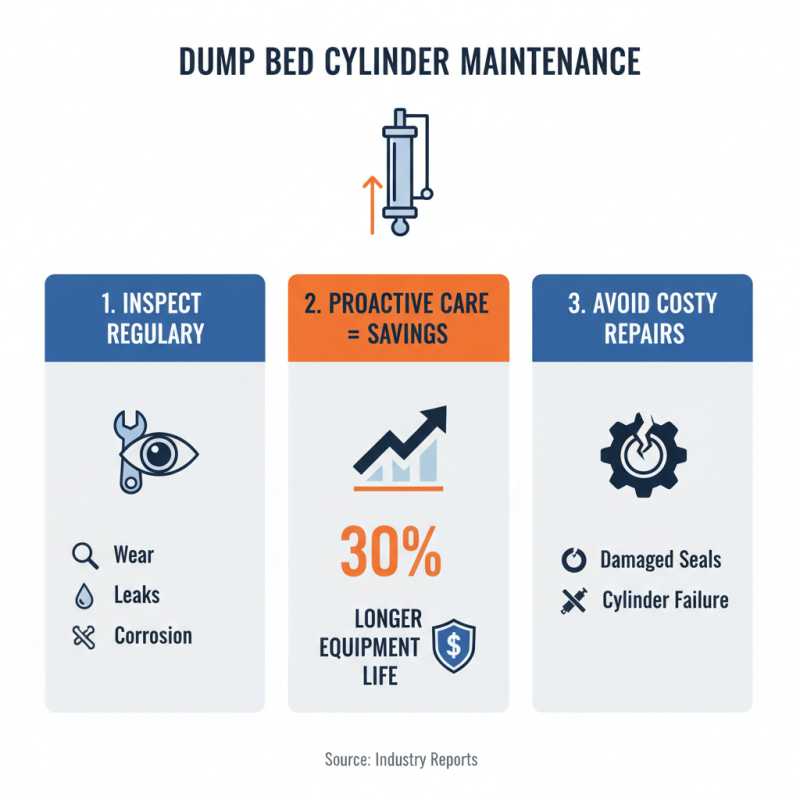

Maintaining dump bed cylinders is crucial for performance and longevity. A key factor is regular inspection. Check for signs of wear, leaks, or corrosion. Industry reports indicate that proactive maintenance can extend equipment life by 30%. Damaged seals or cylinders can lead to costly replacements.

Hydraulic fluid levels should be monitored frequently. Low fluid can cause overheating and damage. The American Society of Mechanical Engineers recommends changing the fluid every 200 hours of operation. This simple step can significantly reduce wear and tear. Operators often overlook this, resulting in avoidable repairs.

Cleaning the cylinders after use helps prevent dirt buildup. Use a soft cloth and safe cleaning agents. Remember, grime can cause big problems. Even small debris can lead to malfunction. Regular maintenance reshapes performance and efficiency. It’s not just about fixing; it’s about prevention. Consider keeping a log of maintenance activity for better tracking.