+86-13349293098

+86-13349293098

Leave Your Message

-

Contact Phone

Contact Phone -

Contact WhatsApp

Contact WhatsApp -

Contact Email

Contact Email

In today’s fast-paced industrial landscape, the role of hydraulic systems cannot be overstated, and at the forefront of this evolution are Hol Mac Hydraulic Cylinders. Designed for efficiency and precision, these hydraulic cylinders are instrumental in a wide array of applications across various sectors. "Hol Mac Hydraulic Cylinders enhance operational efficiency and reliability, making them an essential component in modern industry," states Dr. Emily Carter, a leading expert in hydraulic technology.

The versatility of Hol Mac Hydraulic Cylinders allows them to excel in demanding environments, whether in construction, manufacturing, or transportation. Their ability to deliver high power-to-weight ratios and excellent load handling capabilities increases productivity and reduces downtime. As industries seek to optimize their operations, the benefits of integrating Hol Mac Hydraulic Cylinders have become increasingly recognized.

Moreover, the innovative engineering behind these cylinders contributes significantly to safety and performance. With advanced features that ensure durability and reduce maintenance costs, they are a pivotal asset for companies aiming to stay competitive in an ever-evolving market. As we delve deeper into the top uses and benefits of Hol Mac Hydraulic Cylinders, it becomes clear why they are a preferred choice among industry leaders.

Hol Mac hydraulic cylinders are designed with precision engineering to meet the demanding needs of modern industries. These cylinders feature a robust construction that enhances durability and performance under high-pressure conditions. The use of high-quality materials ensures resilience against wear and tear, making them suitable for applications ranging from heavy machinery operations to automotive manufacturing.

The design of Hol Mac hydraulic cylinders incorporates advanced technologies such as multi-stage sealing systems, which provide superior leakage protection and operational efficiency. Additionally, their compact design enables easy integration into various machinery setups, optimizing space without compromising functionality. The cylinders are also customizable, allowing industries to adapt them to specific applications, whether for lifting, pushing, or pulling heavy loads. This versatility, combined with efficient hydraulic performance, underscores the importance of their design features in enhancing productivity across different sectors.

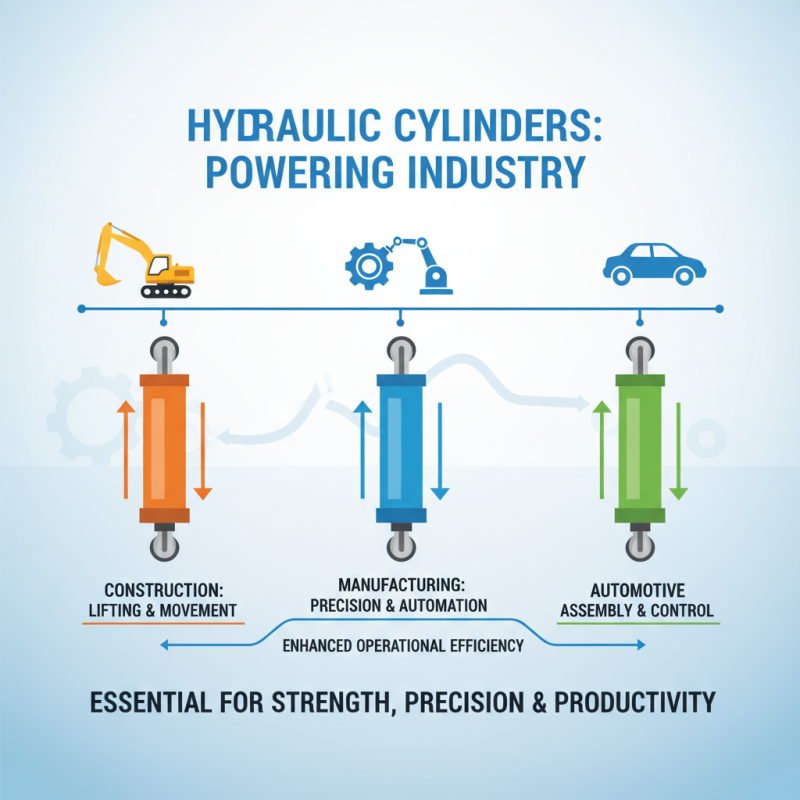

Hydraulic cylinders play a critical role in various industries, providing the necessary force and precision for numerous applications. Among these, the utilization of robust hydraulic cylinders significantly enhances operational efficiency and performance. Industries such as construction, manufacturing, and automotive heavily rely on hydraulic systems to facilitate tasks that require lifting, pushing, or pulling with precision. For instance, in construction, hydraulic cylinders are integral to the operation of heavy machinery, lifting materials and enabling the efficient movement of equipment on job sites.

In the manufacturing sector, hydraulic cylinders are essential for automation processes, where they drive machinery for tasks like pressing, molding, and assembly. Their ability to provide smooth and controlled movements allows for higher production rates and improved product quality. Similarly, the automotive industry employs hydraulic cylinders in various applications, from assembly lines to vehicle maintenance equipment, ensuring that operations are executed swiftly and safely. By leveraging the capabilities of hydraulic cylinders, these key industries experience enhanced performance, translating into increased productivity and reduced operational costs.

Hydraulic cylinders play a crucial role in enhancing the efficiency and reliability of various modern industries. The use of advanced hydraulic systems, particularly Hol Mac hydraulic cylinders, is increasingly favored because of their excellent performance characteristics. These cylinders deliver consistent power, making them ideal for applications in construction, manufacturing, and other sectors that demand precision and strength. Their robust design ensures reduced downtime and maintenance, further contributing to operational efficacy.

Tips: When selecting hydraulic cylinders for your operations, always consider the specifications that align with your specific needs, such as load capacity and stroke length. Additionally, ensure regular maintenance checks to prolong the lifespan of the equipment and maintain optimal performance.

Moreover, the reliability of hydraulic cylinders is significantly enhanced by their ability to withstand varying pressure levels and environmental conditions. This makes them a dependable choice for tasks that require sustained force and durability. By integrating these hydraulic systems into daily operations, industries can experience smoother workflows and decreased chances of mechanical failure, ultimately resulting in higher productivity levels.

Tips: Implementing a preventative maintenance schedule can help identify potential issues before they escalate, ensuring that your hydraulic systems operate at peak performance for longer periods. Keeping thorough records of maintenance can also provide valuable insights for future upgrades and replacements.

This bar chart illustrates the efficiency ratings of hydraulic cylinders across various modern industries, highlighting their importance in enhancing productivity and reliability.

In the competitive landscape of hydraulic cylinders, the choice between Hol Mac hydraulic cylinders and other brands often comes down to performance, durability, and value for money. A comparative analysis reveals that while many brands offer similar specifications, Hol Mac cylinders consistently outperform in terms of reliability and efficiency. Industry reports indicate that equipment downtime associated with inferior hydraulic systems can cost businesses as much as $400,000 per hour in manufacturing sectors. Therefore, investing in high-quality hydraulic cylinders is not merely an upfront cost but a strategic decision that can enhance productivity and operational reliability.

Hol Mac hydraulic cylinders boast advanced engineering that optimizes pressure capacity and extends service life, often exceeding 10,000 operational hours. This longevity contrasts sharply with standard offerings, which may fail after just a fraction of that time under similar operating conditions. Additionally, reports show that cylinders with superior seals and materials can reduce maintenance costs by up to 25%, making them a cost-efficient option in the long run.

**Tips:** When selecting hydraulic cylinders for your operations, consider the total cost of ownership rather than just the initial purchase price. It’s crucial to evaluate lubrication systems and compatibility with existing machinery to ensure you maximize the operational lifespan of your equipment. Regular performance assessments can preemptively identify potential failures, allowing companies to request necessary upgrades or replacements proactively.

Maintenance of Hol Mac hydraulic cylinders is essential to ensure their longevity and optimal performance in various modern industries. Regular servicing and inspections play a crucial role in preventing premature wear and tear. According to a report by the International Hydraulic Association, nearly 30% of hydraulic system failures can be attributed to improper maintenance practices. To mitigate these risks, it is vital to establish a routine check-up schedule, including inspections for leaks, corrosion, and any signs of abnormal wear.

Another critical aspect of maintaining hydraulic cylinders is fluid quality management. The American Society of Mechanical Engineers recommends using high-quality hydraulic fluids that are compatible with the cylinder materials to avoid degradation and buildup of contaminants. Moreover, regular analysis of fluid properties can help identify potential issues before they escalate into significant problems, helping reduce downtime by 25%, as reported by the Hydraulic Institute. Keeping the hydraulic system clean and free from particulates is equally important; implementing filtration systems can drastically improve the longevity of these components, ensuring they operate effectively under varying load conditions.