+86-13349293098

+86-13349293098

Leave Your Message

-

Contact Phone

Contact Phone -

Contact WhatsApp

Contact WhatsApp -

Contact Email

Contact Email

Choosing the right Hydraulic Oil Cylinder can be challenging. Many factors come into play. You need to consider size, capacity, and application.

Hydraulic Oil Cylinders are critical in machinery and equipment. They power various applications, from construction to manufacturing. Selecting the wrong cylinder can lead to inefficiencies and even failures. It's essential to understand your specific needs.

Consider the environment where your Hydraulic Oil Cylinder will operate. Temperature and space constraints matter. Reflect on the load that the cylinder will lift or move. This understanding guides effective choices. Don't rush—take time to evaluate. Making a hasty decision may result in costly mistakes.

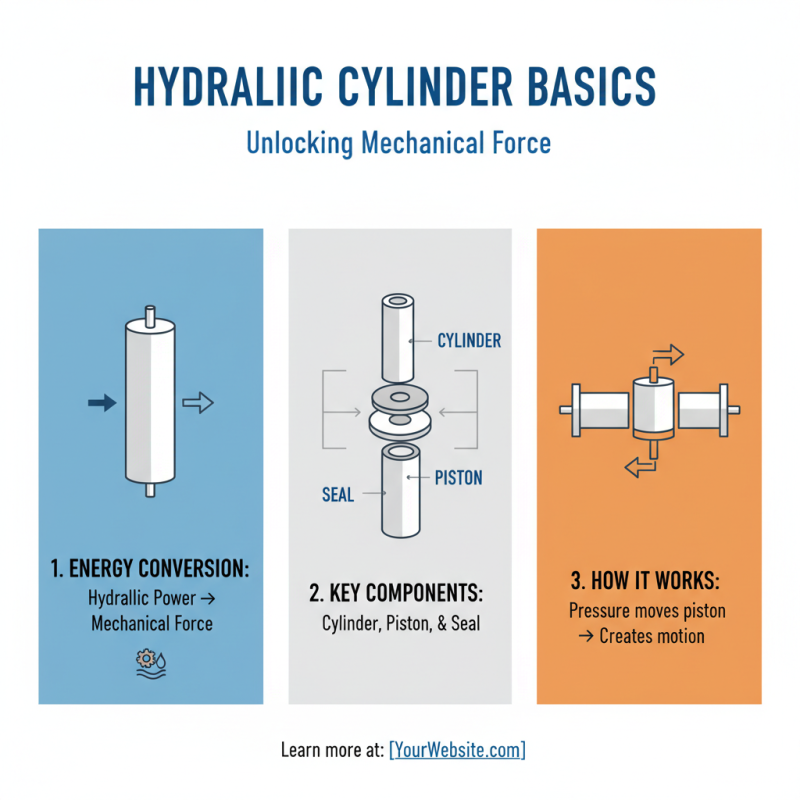

Choosing the right hydraulic oil cylinder involves understanding its basics. Hydraulic oil cylinders convert hydraulic energy into mechanical force. They consist of a cylinder, piston, and seal, working together to create motion.

When selecting a hydraulic oil cylinder, consider the application. What load will it lift? How much pressure will it endure? Size and capacity matter. Too small and it will fail; too large and it may be inefficient. The working environment also plays a critical role. Whether it’s indoors or outdoors can impact material choice.

**Tips:** Always check the specifications before purchasing. Misaligned expectations can lead to costly mistakes. Think about maintenance requirements. Some cylinders may require frequent checks. If overlooked, this can lead to performance drops or even damage.

Deciding on the right hydraulic oil can be daunting. Different types exist, including biodegradable options. Research their suitability for your specific needs. Not all cylinders will perform well in every scenario, so be prepared for some trial and error. Balancing function and efficiency is key.

When selecting a hydraulic oil cylinder, understanding your specific application requirements is crucial. Focus on the working environment. High temperatures or abrasive conditions may require special materials. Consider the load demands as well. If the application involves heavy loads, choose a cylinder with appropriate capacity. Remember, capacity ratings often vary between models, so verify these details carefully.

Piston diameter and stroke length are also vital. A bigger diameter results in more force. However, a longer stroke creates more versatility. Are you working with limited space? A compact design might be necessary. If precision is critical in your operation, actuating speed matters too. Slower speeds can enhance accuracy but may decrease overall efficiency.

Don’t forget to assess pressure ratings. Operating pressure can significantly impact performance. Ensure that the chosen cylinder can handle your project’s specifications. Reflect on your choices as well. Sometimes, a more robust cylinder is not the best fit. Efficiency may be reduced if it’s over-engineered for simple tasks. Balancing specifications with practical needs is essential.

When evaluating different types and designs of hydraulic cylinders, it’s crucial to consider several factors. The choice of design influences performance, efficiency, and longevity of the system. According to the Fluid Power Journal, nearly 30% of hydraulic system failures can be traced back to improper cylinder selection.

Designs vary significantly. Single-acting cylinders are simple and cost-effective. They operate using pressure in one direction only. On the other hand, double-acting cylinders provide more control and power, allowing for movement in both directions. This can lead to increased operational efficiency. However, they can be more complex and expensive. A study from the International Fluid Power Society revealed that nearly 45% of users prefer double-acting designs due to their versatility.

Material choice is another critical aspect. Steel cylinders offer strength but can be heavy. Aluminum is lightweight but may not withstand high pressure. A compromise between strength and weight is often needed. While many users opt for stainless steel for its durability, it can be considerably costlier. Balancing these factors can be difficult, and sometimes the wrong choice can lead to performance issues or even system failures. Understanding your specific application is essential to avoid costly mistakes.

| Cylinder Type | Design Features | Common Applications | Advantages | Limitations |

|---|---|---|---|---|

| Single-Acting Cylinder | Extended stroke with spring return | Lifting applications, compact spaces | Cost-effective, simple design | Lower efficiency in retracting |

| Double-Acting Cylinder | Pressure applied on both sides | Construction, manufacturing | Greater efficiency, full control | More complex, higher cost |

| Tie Rod Cylinder | Two or more tie rods securing cylinder ends | Heavy machinery, industrial applications | Robust, reliable under high pressure | Bulkiness, limited design flexibility |

| Bouquet Cylinder | Multiple cylinders arranged in a pattern | Automotive assembly, robotics | High precision, tight spaces | Complex integration, maintenance challenges |

| Rod-less Cylinder | Magnetic, with no external rod | Factory automation, conveyors | Compact, suitable for tight spaces | Limited stroke, potential for wear |

Choosing the right hydraulic oil cylinder can be challenging. Various factors influence the decision.

Oil specifications play a crucial role in performance and longevity.

Viscosity, for example, is a primary consideration. The Society of Automotive Engineers (SAE) recommends specific viscosity grades for different applications.

An incorrect viscosity can lead to inefficiency and equipment damage.

Another important factor is the oil’s additive package. Additives enhance performance and protect components.

Typical additives include anti-wear agents and antioxidants. A report by the Hydraulic Institute states that quality oil can extend equipment life by 30%.

However, selecting the wrong formulation might hinder performance and increase maintenance costs.

Fluid compatibility is essential too. Not all oils work well with certain seals or materials. This could lead to leaks or premature failure of the cylinder.

Testing compatibility may seem tedious but is necessary for operational efficiency.

Consider all these factors carefully to optimize your hydraulic system's performance.

The right choices can yield significant returns on investment.

When choosing a hydraulic oil cylinder, quality and reliability are crucial. Manufacturers vary in standards and practices. According to a recent industry report, nearly 30% of hydraulic cylinder failures stem from manufacturing defects. This highlights the importance of selecting reputable manufacturers. Pay attention to their production processes and certifications. Ask about materials used and testing protocols. Quality directly affects performance and longevity.

Tips: Always seek out customer reviews. Feedback from other users can provide insights into reliability. Look for manufacturers with a proven track record. Those with longer operational histories often reflect consistent quality.

Not all manufacturers disclose every detail. It can be frustrating, but transparency is key. Inquire about warranty terms and service options. Consider after-sales support; it can make a significant difference later. Reliable brands should be willing to answer all your questions, whether about specifications or corrective measures for defects.

This bar chart displays the quality assessment scores for various hydraulic oil cylinders. Each cylinder's score reflects the manufacturer's reliability and product quality, aiding in the selection process for potential buyers.