+86-13349293098

+86-13349293098

Leave Your Message

-

Contact Phone

Contact Phone -

Contact WhatsApp

Contact WhatsApp -

Contact Email

Contact Email

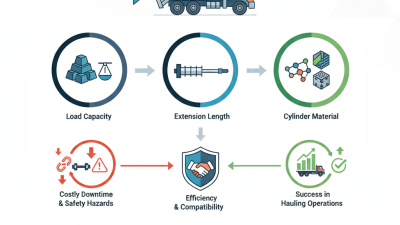

Choosing the right Compact Hydraulic Cylinder can significantly impact your project's efficiency. These cylinders are versatile and powerful, making them popular in various applications. However, selecting the best one for your needs may not be straightforward.

Understanding the specifications of compact hydraulic cylinders is crucial. Factors like size, pressure rating, and stroke length must align with your requirements. Often, users overlook these details, leading to suboptimal performance. A cylinder that is too small may fail to deliver adequate force. Conversely, one that is too large can be inefficient and cumbersome.

Different industries may have unique demands. For example, manufacturing and construction often require durability and precision. Meanwhile, mobile equipment might prioritize weight and compactness. Evaluating these needs is essential. Take time to reflect on your specific application. This will help to avoid mistakes that can lead to increased costs and delays. By doing so, you enhance the chance of successful implementation of your compact hydraulic cylinder.

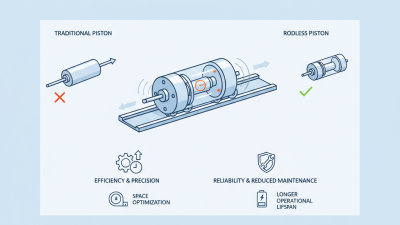

Compact hydraulic cylinders are essential tools in many industries. They are designed to deliver powerful force in a small, efficient package. These cylinders are used in various applications, from manufacturing machinery to mobile equipment. Understanding their structure and function is key to making the right choice.

When considering a compact hydraulic cylinder, it's important to think about your specific needs. What are the load requirements? What space constraints do you have? These questions can guide your selection. Despite their compact size, these cylinders can exert significant force. However, performance can vary based on design and materials. It's crucial to analyze how these variables impact your operations.

Choosing the wrong cylinder can lead to inefficiencies. It can even cause equipment failure. It's not just about size or force; you must also consider the environment in which it will operate. External factors like temperature and humidity can impact performance. So, familiarizing yourself with the features of compact hydraulic cylinders is vital.

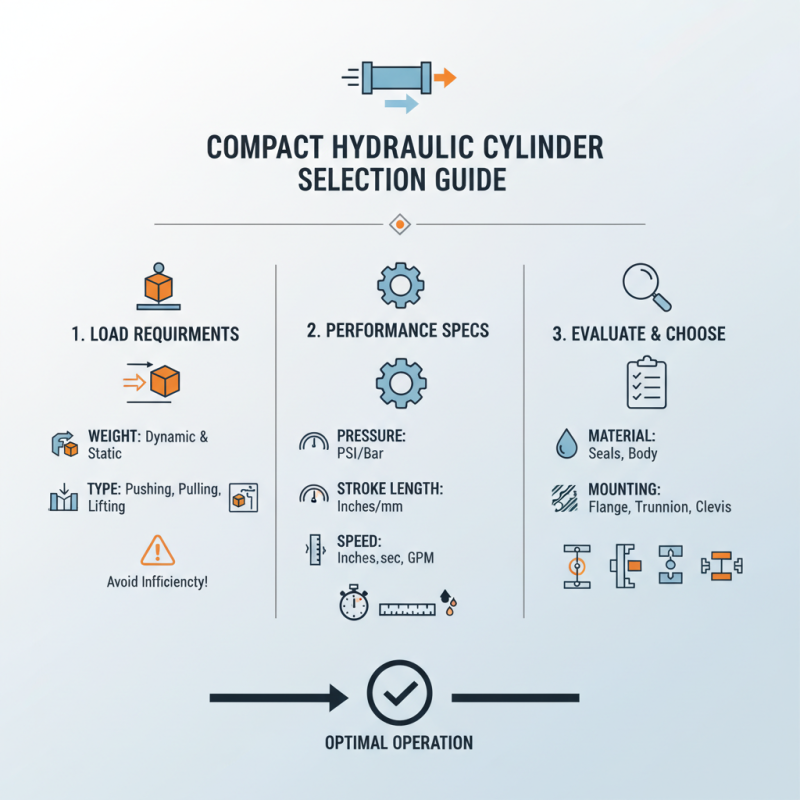

Choosing the right compact hydraulic cylinder is vital for optimal performance. Several key factors can influence your selection process. One critical aspect is the cylinder's bore size, which directly affects force output. Smaller bore sizes yield lower force. Yet, they save space and can fit into tighter spots. According to industry reports, a significant percentage of equipment failure is attributed to improper cylinder sizing.

Another important factor is the operating pressure. Hydraulic systems often work under varying stress levels. It's essential to choose a cylinder that can withstand these pressures without compromising safety. A recent analysis indicated that cylinders operating within their rated pressure can increase lifespan by up to 30%. Additionally, consider the environment where the cylinder will be installed. Exposure to extreme temperatures or harsh chemicals can lead to premature wear or failure.

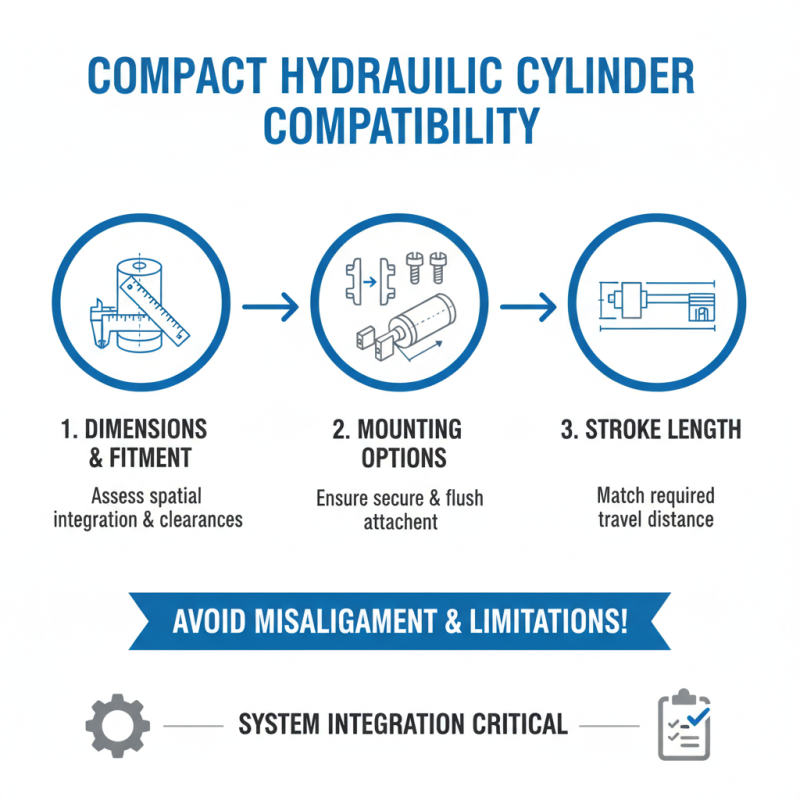

Finally, think about the mounting options and stroke length. Not all applications require the same configurations. Choosing an incompatible mounting type can cause alignment issues quickly. Reflection on these elements can improve performance and durability, leading to a more efficient operation. Each decision should be backed by thorough analysis and testing.

| Key Factor | Description | Importance |

|---|---|---|

| Force Output | Determine the maximum force required for your application. | Critical |

| Stroke Length | Consider the required distance for full extension and retraction. | High |

| Mounting Style | Select a mounting style that fits your equipment design. | Moderate |

| Pressure Rating | Ensure the cylinder can withstand the necessary operating pressure. | Critical |

| Material | Choose a material that offers durability and corrosion resistance. | Important |

| Cylinder Size | Select an appropriate compact size according to space constraints. | High |

Selecting the right compact hydraulic cylinder involves careful evaluation of your load requirements and performance specifications. Start by determining the weight and type of load you will be moving. Consider the dynamic and static loads. Incorrect assessments can lead to inefficient operation.

Next, identify the required stroke length. Too short, and you won't achieve your goals. Too long, and you waste space and energy. Think about the working environment. Extreme temperatures or contamination can affect performance. Ensuring that the cylinder can withstand these conditions is crucial.

Finally, reflect on the mounting options and connector types. Poor compatibility can lead to installation difficulties. Evaluate the need for specific features, such as adjustable speed control. These can enhance functionality but might complicate the design. The process is complex, and overlooking key factors can impact results.

When selecting a compact hydraulic cylinder, understanding its compatibility with existing systems is vital. Assess how the cylinder dimensions fit into your current setup. Check the mounting options. Ensure the cylinder can attach seamlessly. Misalignment can cause issues later on. Confirm that the stroke length meets your requirements. Too short, and you’ll face limitations; too long, and you may have excess movement.

Next, consider the hydraulic fluid types already in use. Different fluids can affect cylinder performance. Establishing the right seals is essential. Improper sealing can lead to leaks. Avoid common mistakes like neglecting the pressure ratings of both the cylinder and your system. They must align to prevent breakdowns. Understand that every detail counts. Small oversights can lead to expensive repairs down the road.

When selecting a compact hydraulic cylinder, maintenance is key for reliability. Regular inspections help prevent unexpected failures. Inspect seals and connections routinely. Look for leaks or unusual noises. A small issue can evolve into a costly problem. Pay attention to the operating environment. Dust and moisture can impair functionality over time.

Lubrication is critical for long-term performance. Using the right lubricant reduces friction and extends life. Some users overlook this detail. They find themselves facing decreased productivity due to wear and tear. Keeping a maintenance log can help track service intervals. This encourages a proactive approach.

It’s also important to ensure compatibility with existing systems. Mismatched components can lead to inefficiency. Inconsistencies may not be apparent at first. Over time, they can result in significant operational challenges. Reflect on your requirements and adapt accordingly. The right choices come from a blend of knowledge and willingness to learn from past experiences.

This bar chart illustrates the importance level of various criteria when choosing a compact hydraulic cylinder. Factors such as size, weight, pressure rating, cycle life, and maintenance frequency are assessed on a scale from 0 to 100, indicating their relevance in the selection process.